Production Line

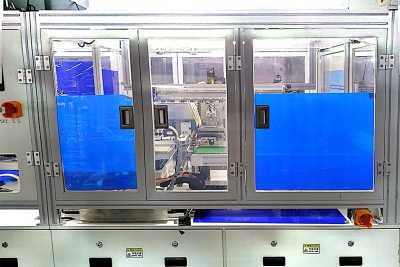

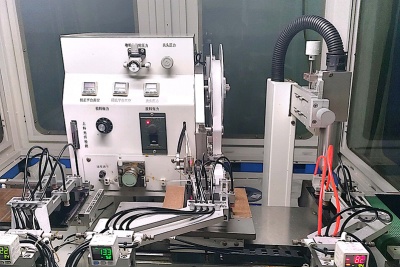

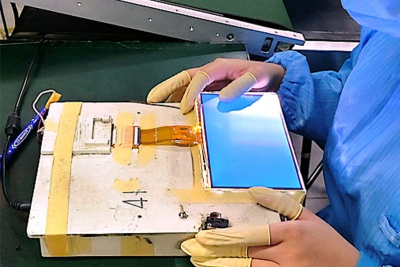

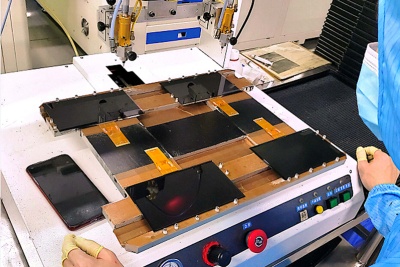

LCM Workshop

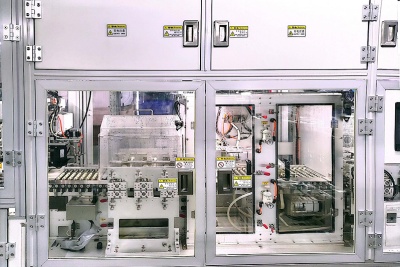

LCM Workshop covers an area of 2000 square meters and houses a comprehensive manufacturing division that produces B/L (Backlight), LCM (Module), and various LCD products ranging from 3.5 inches to 17 inches in size. The division is equipped to specialize in optoelectronic product manufacturing. The workshop maintains a controlled environment with a cleanliness level of 10000 in general areas, 1000 in specific zones, and a dedicated dust-free space of 1500 square meters.

To ensure cutting-edge production capabilities, the company has introduced a batch of state-of-the-art fully automatic COG Bonding equipment and TFT production processing lines, along with 4 assembly lines for backlight assembly and 2 standard production lines. The combined capacity of these facilities ranges from 15,000 to 25,000 units per day.

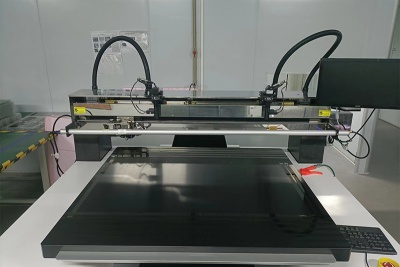

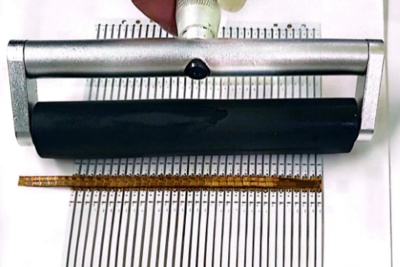

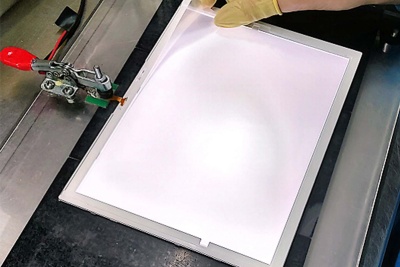

LCD Large Board Cutting

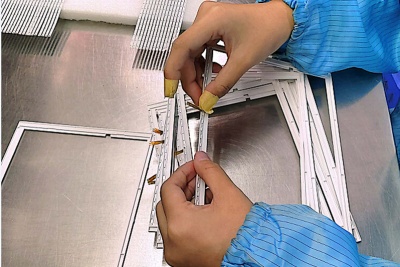

LCD Substrate Splitting

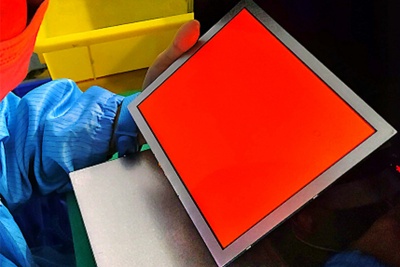

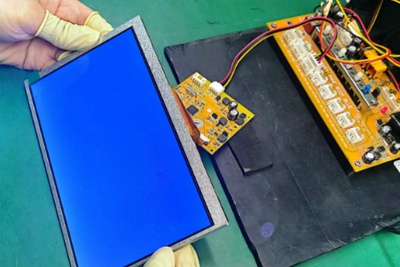

LCD Full Inspection and Electrical Testing

LCD Cleaning

LCD Appearance Inspection

Fully Automatic Feeding

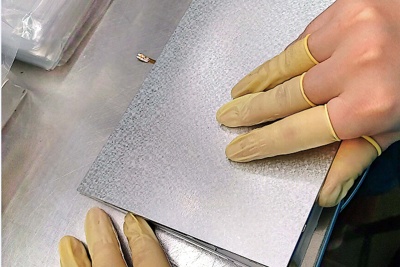

Grinding and Cleaning

Baking and Dry

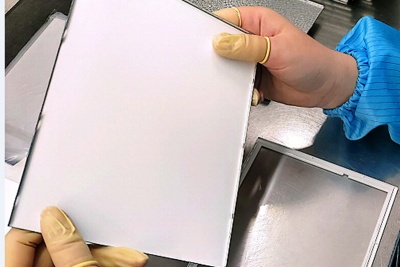

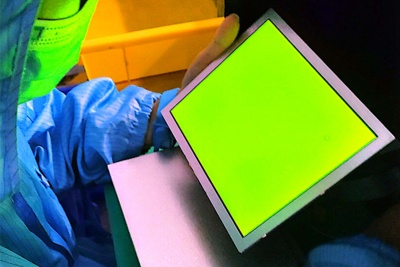

Patching Top Polarizer

Patching Bottom Polarizer

Appearance Inspection

Defoaming

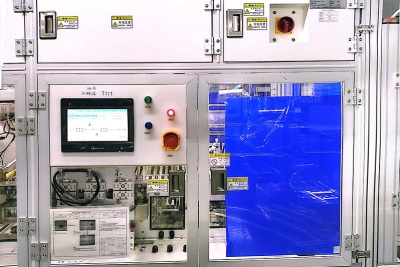

Fully Automatic Feeding

LCD ITO Cleaning/Baking

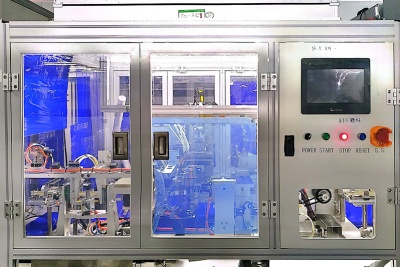

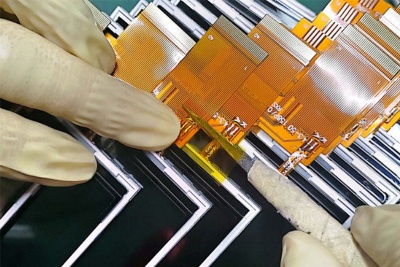

IC ACF Attachment

FOG ACF Attachment

FOG Hot Press (Fake/Original Press)

FOG Electrical Testing

FPC Attachment with Reinforcing Adhesive

ITO Terminal Gluing

FOG Appearance Inspection

Glue Coating of Light Bar

Glue Frame Stick Light Strip

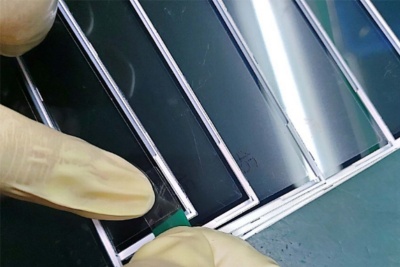

Assemble Light Guide Plate

Assemble Reflective Film

Assemble Lower Iron Frame

Assemble Diffusion Film/Enhancement Film

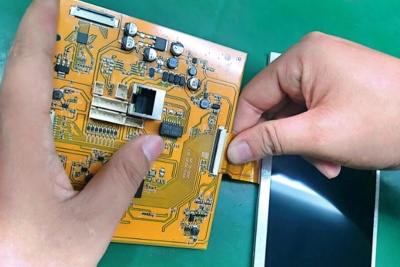

Assemble FOG (Fiber Optic Glass)

Assemble Upper Iron Frame

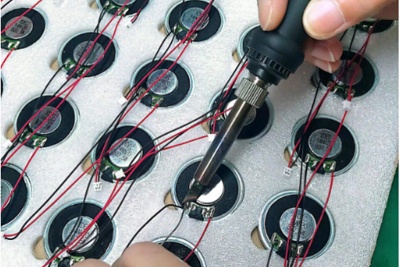

Backlight Welding

Functional Testing

Glue High-Temperature Solder Pads

Attach Easy Tear Tape

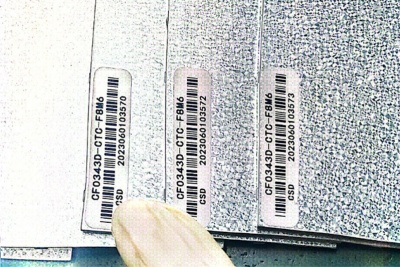

Attach Product Labels

FQC Functional Testing

Appearance Inspection

OQC Sampling Inspection

Packaging

Storage

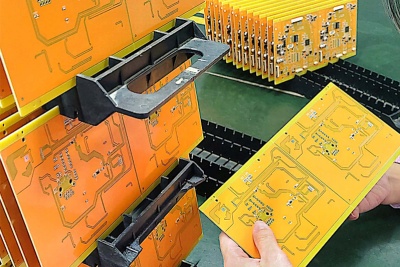

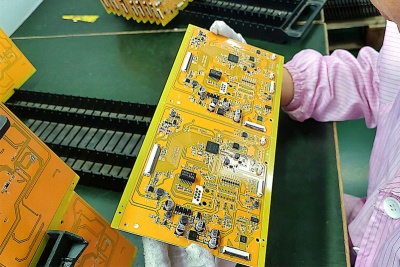

SMT Workshop

The SMT (Surface Mount Technology) workshop covers an area of 1000 square meters. The workshop is fully equipped with imported machines, comprising five production lines. Each line has a capacity of over 500,000 components, resulting in a total capacity of more than 2 million components for the four lines combined. The company’s current equipment includes:

1. Three sets of Timely High-Speed Automatic Screen Printers (CP743).

2. Two sets of QP Multifunction Automatic Unloaders.

3. Two sets of Reflow Soldering Machines.

4. Two sets of AIO Testing Equipment.

5. Two backend production plugin lines.

PCB Loading

Printing

Solder Paste Inspection

SMT for Small Components

SMT for Type A Components

Over Transfer Machine

Reflow Soldering

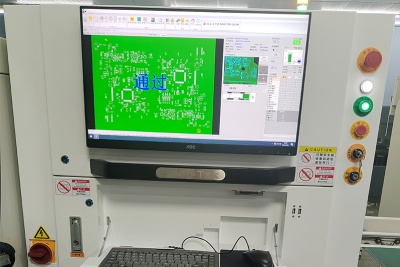

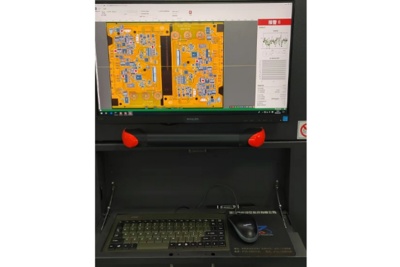

AOI (Automated Optical Inspection)

Post Welding

Appearance Inspection

Plugin Insertion

Wave Soldering

FQC (Final Quality Control) Inspection

Packaging

Warehousing

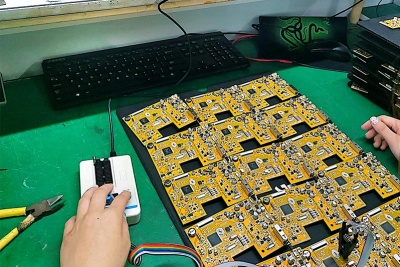

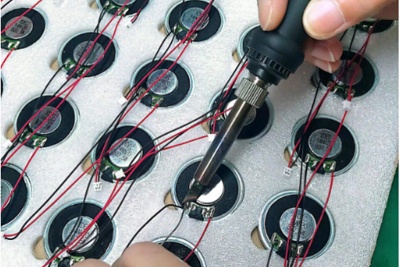

Indoor Monitor Assembly Workshop

The assembly workshop covers an area of about 2000 ㎡ , while the warehouse occupies around 2500 ㎡. The workshop is equipped with four brand-new professional assembly lines, each measuring 50 meters in length, along with corresponding testing,trial equipment and a large team of skilled assembly workers, quality inspectors, and excellent professional management personnel. The workshop is capable of assembling and testing various video door phone intercom devices with a daily production capacity of 3000-4000 units. Additionally, it can handle video driver module product assembly and testing with a daily production capacity of 8000-10000 units, as well as assembly and testing of OEM/ODM mainboards for video door phone intercoms with a daily production capacity of 5000-8000 units.

Motherboard Burning Software

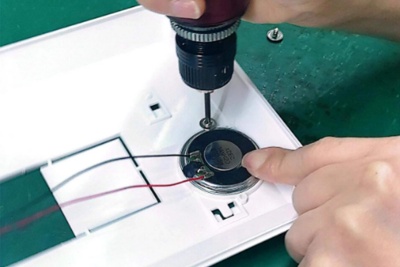

Welding Horn

Lock Horn

Panel Sssembly Module

Install lenses

Install Module

Lock Motherboard &Install Microphone

Lock Back Cover

Failed – Repair

Packaging

Warehousing

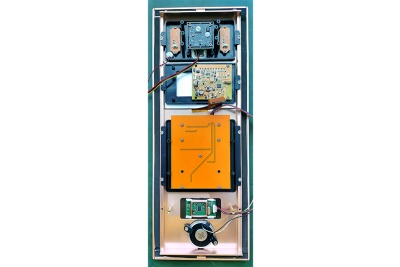

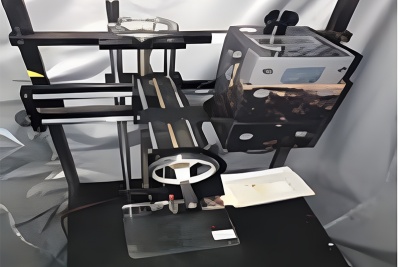

Outdoor Station Assembly Workshop

The assembly workshop covers an area of about 2000 ㎡ , while the warehouse occupies around 2500 ㎡. The workshop is equipped with four brand-new professional assembly lines, each measuring 50 meters in length, along with corresponding testing,trial equipment and a large team of skilled assembly workers, quality inspectors, and excellent professional management personnel. The workshop is capable of assembling and testing various video door phone intercom devices with a daily production capacity of 3000-4000 units. Additionally, it can handle video driver module product assembly and testing with a daily production capacity of 8000-10000 units, as well as assembly and testing of OEM/ODM mainboards for video door phone intercoms with a daily production capacity of 5000-8000 units.

Install Waterproof Gasket on the Upper Edge

Attach EV Pad to the Display Bracket

Waterproof Pad for Key Holder

Welding Horn Wire

Lock Top and Bottom Guards / Install lenses

Install Display/ Lock Display Stand

Install Camera Bracket/Install Camera

Light Board/ Body Detection Module

Install Button / Lock Button Bracket

Install Keypad/ Install Bluetooth Module

Install Brush Plate /Lock Horn

Install Motherboard/ Lock Back Cover

Failed Test- To Repair

Pass Test-To Package

Warehousing

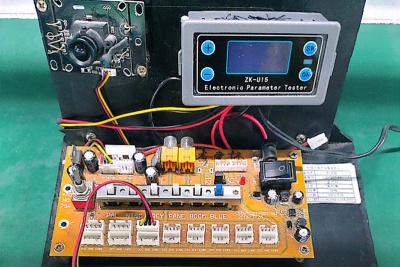

Finished Product Test Equipments

Screen Testing Racks (30 sets )

Motherboard Testing Racks (50 sets )

Aging Test (17 rows)

High and Low Temperature/ Hot and Cold Shock Test Chamber

Salt Spray Test

Vibration Test

Package Drop Test

FPC Tension Testing Machine

Mirror Microscope

BM-7 Backlight Brightness Tester

Power Burn-in Test

Automated Optical Inspection (AOI)

Factory Warehouse

LCM Material Warehouse

IC Warehouse

Electronic Material Warehouse

PCB Board Warehouse

Whole Machine Material Bin